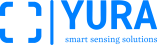

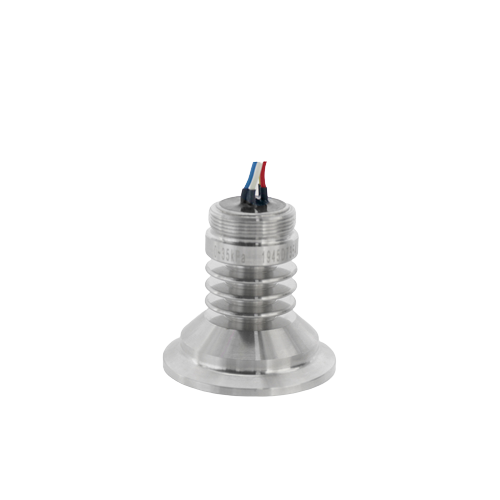

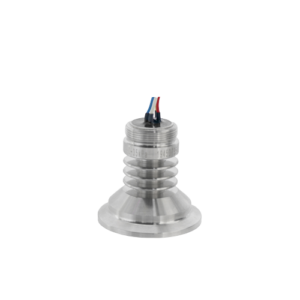

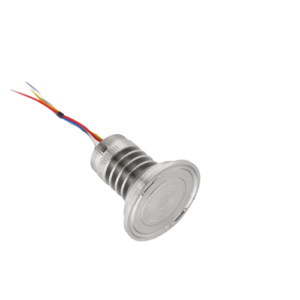

YURA30 Flush pressure sensor

YURA30 Flush pressure sensor

Piezoresistive Silicon Pressure Sensor

Application: Medical and pharma Hygienically-graded pressure sensor food and beverage industry.

Measuring range: -100kPa~0~35kPa…7MPa

Process temperature: -40~85℃

Material: SS 316L

Size: 1-1/2” Tri-clamp, 2” Tri-clamp

Imported highly reliable pressure

Sensing die

Product

YURA30 OEM pressure sensor is a high-precision and High stable piezoresistive sensor, equipped with state-of-the-art pressure-sensitive chips. It is crafted with meticulous care, utilizing advanced technology, and adhering to stringent military-industry production standards. This sensor finds versatile applications across various industries, including petroleum, chemical, metallurgy, electric power, aviation, and medical equipment.

The YURA30 series pressure sensors cutting-edge engineering and precision components, boasting a silicon pressure chip known for its high stability. These sensors feature a stress-optimized sintered seat and undergo a rigorous manufacturing process involving Surface Mount Device (SMD) technology, gold wire bonding, diaphragm welding, high vacuum oiling, stress relief procedures, high-temperature aging, and temperature compensation.

Features

Measuring Range: -100kPa~0~35kPa…7MPa, offering versatile pressure measurement capabilities.

Pressure Types: Available in gauge pressure (G), absolute pressure (A), and sealing gauge pressure (S) configurations.

Power Supply Options: Supports both constant current and voltage power supplies.

Isolated Structure: Suitable for use with a variety of fluid media.

Size: 1-1/2” Tri-clamp, 2” Tri-clamp pressure sensor size.

Material: Constructed with high-quality 316L stainless steel for durability and reliability. all stainless-steel construction makes it suitable for the harshest industrial environments

Electrical specifications

Power Supply: ≤ 3.0mA; DC ≤ 10V

Connection: 0.2mm² 4-color 100 mm silicone rubber flexible conductor Common Mode Voltage Output: 50% of current mode input (typical value), 40% of voltage type input (typical value)

Input Impedance: 2.7K Ω ~ 5K Ω

Output Impedance: 3.0k Ω ~ 6K Ω

Response Time (10% ~ 90%): < 1ms

Insulation Resistance: 500M Ω / 100V DC

Allowable Overvoltage: 1.5 times of full scale

Mechanical specifications

Diaphragm Material: Stainless Steel 316L

Titanium TA1(optional)

Shell Material: Stainless Steel 316L

Titanium TA1(optional)

Pressure Lead-in Tube Material: Stainless Steel 316L

Pin Lead: Gilded Kovar gold plated pins

Sealing Ring: Nitrile Rubber / Viton(optional)

Wiring

Wire Colour current:

Red: Excitation Positive (+) or IN+

Blue: Excitation Negative (-) or IN-

Yellow: Output Positive (+) or OUT+

White: Output Negative (-) or OUT-

Wire Colour voltage:

Red: Excitation Positive (+) or IN+

Black: Excitation Negative (-) or IN-

Blue: Output Positive (+) or OUT+

Yellow: Output Negative (-) or OUT-

Technical Parameters

| Operating pressure range | -100kPa~0~35kPa…7MPa |

| Zero output | ±1 mV |

| Nonlinearity | 0.2% of full scale (FS) |

| Hysteresis | 0.05% of FS |

| Repeatability | 0.05% of FS |

| Input/output impedance | 2.6 kΩ to 3.8 kΩ |

| Zero temperature drift | ±0.15% of FS at 25℃ |

| Sensitivity temperature drift | ±0.2% of FS at 25℃ |

| Long-term stability | 0.1% of FS per year |

| Excitation current | 1.5 mA (maximum input voltage is 10 VDC) |

| Insulation resistance | 500 MΩ (500 VDC) |

| Compensation temperature | 0~50; -10~80℃ |

| Operating temperature | -40~+85℃ |

| Storage temperature | -40~+125℃ |

| Response time | ≤1 ms |

| Shell & diaphragm material | 316L stainless steel |

| Measuring medium | Medium compatible with 316L, Nitrile Rubber / Viton. |

| Vibration (20~500 Hz) | 20 G |

| Useful time (25℃) | >1*108 pressure circulation (80% of FS) times |

| Filling oil | Silicon oil / Fluorine oil/FDA |

Note: The typical value of 0~10 kPa and 0~20 kPa’s zero temperature drift and sensitivity temperature drift are 0.4% of FS at 25℃, the maximum value is 1.6% of FS at 25℃.

Standard Range

| Range | Overload Pressure | Full Scale Output(mV) | Typical Value(mV) | Pressure Form |

| 0~10 kPa | 300% | 35~60 | 45 | G |

| 0~20 kPa | 300% | 70~110 | 90 | G |

| 0~35 kPa | 300% | 55~80 | 70 | G/A |

| 0~70 kPa | 300% | 55~80 | 60 | G/A |

| 0~100 kPa | 300% | 60~85 | 75 | G/A |

| 0~200 kPa | 300% | 65~85 | 75 | G/A |

| 0~400 kPa | 300% | 60~80 | 70 | G/A |

| 0~600 kPa | 200% | 90~120 | 100 | G/A |

| 0~1.6 MPa | 200% | 80~120 | 100 | G/A |

| 0~1.0 MPa | 200% | 125~185 | 150 | G/A |

| 0~2.0 MPa | 200% | 50~70 | 60 | G/A |

| 0~3.5 MPa | 200% | 100~120 | 110 | G/A |

| 0~7.0 MPa | 200% | 120~150 | 135 | A |

| 0~10 MPa | 200% | 180~230 | 200 | A |

| 0~25 MPa | 150% | 140~170 | 150 | A |

| 0~40 MPa | 150% | 230~280 | 250 | A |

| 0~60 MPa | 150% | 100~160 | 130 | S |

| 0~100 MPa | 150% | 100~150 | 120 | S |

| Notes: | ||||

| G = gauge pressure | ||||

| A = absolute pressure | ||||

| S = sealed gauge pressure. | ||||

Drawings

| Model | Pressure Range | Type | Drawing |

| YURA30 | -100kPa~7MPa | YURA3001 (-40℃~+85℃) | |

YURA3002 (-40℃~+150℃) |

Ordering

| YURA30 | Piezoresistive Silicon Pressure Sensor | |||||

| Range code | Pressure Range | Ref | Range code | Pressure Range | Ref | |

| A1 | 0…10kPa | G | A9 | 0…3.5MPa | G/S/A | |

| A2 | 0…35kPa | G/A | A10 | 0…6MPa | S | |

| A3 | 0…70kPa | G/A | A11 | 0…10MPa | S | |

| A4 | 0…100kPa | G/A | A12 | 0…25MPa | S | |

| A5 | 0…200kPa | G/A | A13 | 0…40MPa | S | |

| A6 | 0…400kPa | G/A | A14 | 0…60MPa | S | |

| A7 | 0…1.0MPa | G/A | A15 | 0…100MPa | S | |

| A8 | 0…2.0MPa | G/A | AXX | Custom | ||

| Code | Pressure type | |||||

| B1 | Gauge | |||||

| B2 | Absolute | |||||

| B3 | Sealed gauge | |||||

| Code | Type/Output | |||||

| C1 | Constant Current | |||||

| C2 | Constant Voltage | |||||

| C3 | I2C (Inter-Integrated Circuit) | |||||

| Code | Electric connection | |||||

| D1 | 100mm silicon rubber flexible wires | |||||

| D2 | 4pins | |||||

| Code | Size | |||||

| E1 | 1-1/2” Tri-clamp | |||||

| E2 | 2” Tri-clamp | |||||

| EX | Special size | |||||

| YURA30 | A1 | B2 | C2 | D1 | E1 | |

Realated Product

YURA19 OEM Pressure Sensor

YURA20 Flush pressure sensor

YURA40 Differential pressure sensor

YURA101 Pressure transmitter

YURA201 Flush Pressure transmitte

YURA301 Flush Pressure transmitter

YURA401 Differential Pressure Transmitter

YURA500 Monocrystalline Silicon Pressure Sensor

YURA501 Monocrystalline silicon pressure sensor assembly

YURA600 Monocrystalline silicon differential pressure sensor

YURA601 Monocrystalline silicon differential pressure sensor assembly

YURA3051DP Intelligent differential pressure transmitter